Industrial ERP software is crucial for business operations due to its advanced features that streamline processes and boost efficiency. With integrated modules for inventory management, production planning, and resource allocation, ERP software provides real-time data and analytics for informed decision-making. It enables seamless collaboration across departments, automates workflows, reduces errors, and optimizes resource utilization. This results in increased productivity, cost savings, and improved customer satisfaction. Invest in industrial ERP software to gain a competitive edge in today’s fast-paced business landscape.

In today’s fast-paced and competitive business landscape, efficiency and productivity are crucial for success. One tool that has revolutionized the way businesses operate is industrial ERP software. With its comprehensive features and capabilities, industrial ERP software streamlines operations, enhances collaboration, and provides real-time visibility into key business processes. It has become an essential tool for organizations to stay ahead of the curve and thrive in the digital age.

Industrial ERP software has a rich history, dating back to the 1960s when organizations began using computer systems to manage their manufacturing processes. Over the years, the software has evolved to incorporate advanced technologies such as artificial intelligence, machine learning, and cloud computing. Today, it offers a wide range of benefits, including improved inventory management, optimized production scheduling, enhanced supply chain visibility, and efficient resource allocation. In fact, studies have shown that companies that implement industrial ERP software experience significant cost savings, increased revenue, and improved customer satisfaction.

The Importance of Industrial ERP Software for Business Efficiency

In today’s competitive business landscape, companies are constantly looking for ways to improve their operational efficiency and gain a competitive edge. One area where businesses can significantly improve efficiency is through the implementation of industrial ERP (Enterprise Resource Planning) software. ERP software is a comprehensive business management solution that integrates various essential functions such as finance, human resources, supply chain management, and customer relationship management into a single system. This article explores why industrial ERP software is a necessity for businesses and how it can drive efficiency and profitability.

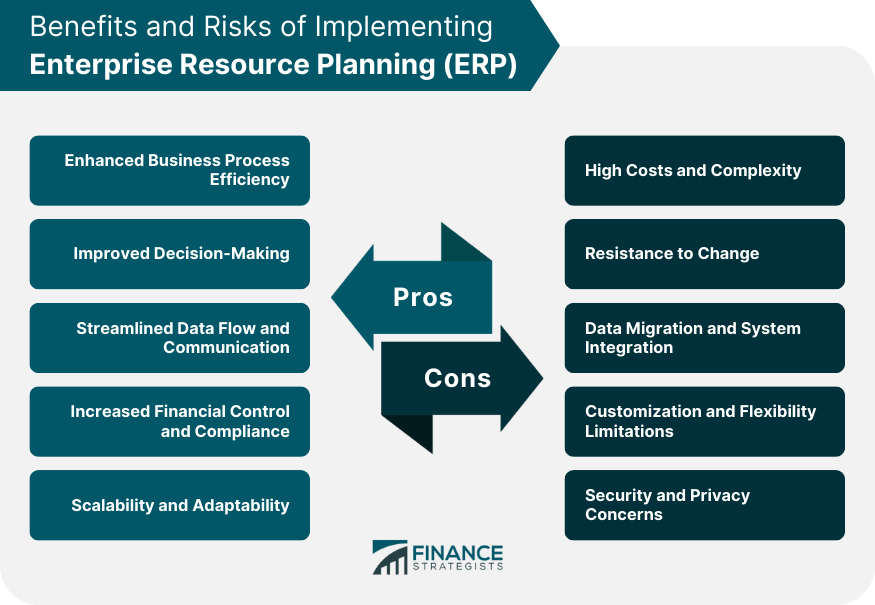

Industrial ERP software offers a wide range of benefits that can have a profound impact on a company’s operations. Firstly, one of the key advantages of ERP software is streamlining and automating processes. With ERP, businesses can eliminate manual and repetitive tasks, reducing the chance of errors and freeing up valuable human resources for more strategic activities. By automating processes, companies can achieve greater accuracy, productivity, and efficiency, ultimately leading to cost savings and improved customer satisfaction. This level of streamlining is especially critical for industries such as manufacturing, distribution, and logistics where operations can be complex and time-sensitive.

Secondly, industrial ERP software enables better decision-making by providing real-time, accurate, and actionable insights. By consolidating data from different departments and functions, ERP software delivers a holistic view of the business, allowing managers and executives to make informed decisions based on data-driven insights. This level of visibility and transparency empowers businesses to respond quickly to market dynamics, identify trends, and optimize processes for improved performance. For example, ERP software can generate reports and analytics on key performance indicators (KPIs) such as inventory levels, production cycle times, and customer satisfaction, enabling companies to identify areas for improvement and take proactive measures to address them.

The benefits of industrial ERP software extend beyond internal operations and can also have a significant impact on supply chain management. ERP software enables seamless integration with suppliers, vendors, and customers, creating a networked ecosystem that enhances collaboration and efficiency across the entire supply chain. Through features like electronic data interchange (EDI) and real-time inventory management, companies can improve communication, reduce lead times, and optimize inventory levels. This level of integration and visibility ensures that supply chain operations are well-coordinated, minimizing disruptions and maximizing customer satisfaction. Overall, industrial ERP software provides businesses with the necessary tools and capabilities to operate efficiently and stay competitive in today’s fast-paced business environment.

Cost Savings and Financial Management with Industrial ERP Software

Another compelling reason for businesses to leverage industrial ERP software is the potential for significant cost savings and improved financial management. ERP software offers a range of features and functionalities that are specifically designed to optimize financial processes and help businesses make sound financial decisions.

One of the key financial benefits of industrial ERP software is accurate forecasting and budgeting. By integrating data from various departments, ERP software provides a comprehensive view of the company’s financial position, enabling better forecasting and budgeting accuracy. With real-time data and advanced analytics, businesses can identify cost-saving opportunities, allocate resources effectively, and create realistic financial plans. This level of visibility into financial data ensures that businesses can make informed decisions about investments, expenses, and overall financial strategy.

In addition to accurate forecasting, ERP software also enables efficient financial reporting and analysis. With built-in reporting tools and customizable dashboards, businesses can generate accurate and up-to-date financial reports, such as balance sheets, income statements, and cash flow statements. These reports provide valuable insights into the company’s financial health, allowing management to identify trends, track performance, and make data-driven decisions. Furthermore, ERP software can automate the consolidation of financial data from multiple entities or subsidiaries, simplifying the financial reporting process for multinational or decentralized companies.

Moreover, industrial ERP software helps businesses optimize cash flow management. By automating accounts receivable and accounts payable processes, companies can streamline billing and invoicing, improve collection processes, and reduce the risk of late payments or missed opportunities for early payment discounts. ERP software also enables efficient cash flow forecasting by integrating data on sales, expenses, and payment terms, allowing businesses to plan and manage their cash flow effectively. This level of financial management and optimization can have a significant impact on a company’s bottom line and overall financial stability.

Lastly, industrial ERP software provides businesses with enhanced compliance and risk management. With features like built-in audit trails, rigorous security controls, and role-based access, ERP software ensures that financial data is protected, transactions are accurate, and regulatory compliance is maintained. This level of governance and control not only mitigates the risk of fraud or financial errors but also instills confidence in stakeholders such as shareholders, auditors, and regulatory authorities. By leveraging industrial ERP software, businesses can effectively manage financial risks, ensure compliance with industry regulations, and protect their reputation.

Enhancing Productivity and Collaboration through Industrial ERP Software

In today’s interconnected and fast-paced business landscape, collaboration and efficiency have become more critical than ever. Industrial ERP software plays a vital role in promoting productivity, collaboration, and knowledge sharing within an organization.

Firstly, ERP software improves productivity by streamlining and automating key business processes. It eliminates manual data entry and redundant tasks, allowing employees to focus on value-added activities that contribute to the company’s growth. For instance, ERP software can automate order processing, inventory management, and accounts payable, reducing the time and effort required to complete these tasks manually. This automation not only increases productivity but also reduces the chance of errors and enables employees to work more efficiently.

Secondly, industrial ERP software enhances collaboration by breaking down silos and promoting cross-departmental communication and knowledge sharing. ERP software provides a centralized platform where employees from different departments can access and share real-time data and information. This level of collaboration improves coordination, accelerates decision-making, and ensures that everyone is working with the same accurate and up-to-date information. For example, a salesperson can access inventory data to provide accurate delivery timelines to a customer, or a production manager can share production schedules with the procurement team to ensure timely material availability.

Furthermore, ERP software enables remote access and mobile capabilities, allowing employees to work from anywhere, anytime. This flexibility promotes a culture of remote work and empowers employees to stay connected and productive even when they are not physically present in the office. Whether it’s approving purchase orders, reviewing sales reports, or accessing customer information, employees can perform their tasks and access critical information on-the-go, improving responsiveness and agility.

Conclusion

In conclusion, industrial ERP software is no longer a luxury but a necessity for businesses looking to enhance efficiency, drive profitability, and gain a competitive edge. ERP software not only streamlines and automates processes but also provides accurate and actionable insights for better decision-making. It enables cost savings, improves financial management, and ensures compliance. Additionally, ERP software enhances productivity, collaboration, and knowledge sharing within organizations. By leveraging industrial ERP software, businesses can optimize their operations, improve customer satisfaction, and thrive in today’s fast-paced business environment.

Frequently Asked Questions

Here are some common questions about the need for industrial ERP software for business:

1. What is industrial ERP software and why do businesses need it?

Industrial ERP software, or Enterprise Resource Planning software, is a comprehensive solution designed to manage and integrate all aspects of a business, including finance, inventory, HR, production, and more. Businesses need ERP software to streamline their operations, improve productivity, enhance decision-making, and increase efficiency. It provides real-time visibility into business processes, automates repetitive tasks, and enables better resource planning.

Additionally, industrial ERP software offers advanced functionality specific to industrial businesses, such as supply chain management, demand forecasting, production scheduling, and quality control. This specialized functionality enables better control and optimization of industrial processes, leading to cost savings and improved customer satisfaction.

2. Can’t businesses manage their operations without industrial ERP software?

While it is possible for businesses to manage their operations without industrial ERP software, it can be a highly challenging and inefficient process. Without an integrated software solution, businesses often rely on manual processes, spreadsheets, and multiple disconnected systems, which can lead to errors, data inconsistencies, and information silos.

Industrial ERP software provides a centralized platform for managing all business operations, facilitating seamless communication between different departments and functions. It eliminates redundant data entry, ensures data accuracy, and enables real-time collaboration, improving overall operational efficiency and effectiveness.

3. How does industrial ERP software benefit inventory management?

Industrial ERP software plays a crucial role in inventory management by providing accurate, up-to-date information about inventory levels, stock locations, and demand. It enables businesses to optimize inventory holding, reduce carrying costs, and prevent stockouts or overstocks. With advanced forecasting capabilities, businesses can analyze historical data, predict future demand, and plan their inventory accordingly.

Furthermore, industrial ERP software enables efficient order processing and fulfillment. It automates the entire order lifecycle, from order entry to shipment, ensuring timely delivery and customer satisfaction. With real-time inventory visibility, businesses can avoid backorders and expedite order processing, resulting in improved customer service and increased sales.

4. How does industrial ERP software help with financial management?

Industrial ERP software is equipped with powerful financial management capabilities. It enables businesses to streamline financial processes such as accounts receivable, accounts payable, general ledger, and budgeting. It automates financial transactions, eliminates manual errors, and provides real-time financial visibility.

With industrial ERP software, businesses can generate accurate and timely financial reports, such as income statements and balance sheets. This helps in monitoring financial performance, identifying areas for cost reduction, and making informed financial decisions. The software also ensures compliance with accounting standards and regulations, reducing the risk of financial inaccuracies or penalties.

5. Is industrial ERP software scalable for growing businesses?

Absolutely! Industrial ERP software is designed to be scalable and adaptable to the changing needs of businesses. As businesses grow and expand, the software can easily accommodate increased transaction volumes, additional users, and new functionalities. It provides flexibility to add modules or customize the software to meet specific business requirements.

Moreover, industrial ERP software supports multi-site and multi-company operations, enabling businesses with multiple locations or entities to manage their operations seamlessly. Whether a business is small or large, industrial ERP software can scale accordingly, ensuring continued efficiency and effectiveness in managing the business processes.

Industrial ERP software is essential for businesses because it helps streamline operations and improve overall efficiency. By integrating various functions like finance, inventory management, and production planning, ERP software enables businesses to have better control and visibility over their entire operations.

With industrial ERP software, businesses can automate manual processes, reduce errors, and make faster and more informed decisions. It eliminates the need for separate systems and data silos, allowing for real-time data sharing and analysis across departments. This enables businesses to optimize resources, reduce costs, and enhance customer satisfaction, ultimately driving growth and success.